|

Enveloping is one of the most

utilized methods to diagnose bearings. This technique is based

on the constructive characteristics of the bearings and is able

to find shocks and friction even from the very beginning of a

flaw.

Bearing casing vibrations

The bearing case can vibrate for multiple reasons: imbalances,

misalignments, shocks, etc. Unlike the other vibration sources,

following the high speed forces variation, the shocks may excite

the bearing case at its resonance frequency.

Of interest in the bearing diagnosis are the occurrence

frequency and amplitude of such oscillations.

Although the resonance frequency manifests within a rather

narrow frequency band, the amplitude modulation process resulted

from those shocks and the variation of the transmission

conditions, calls for an analysis over a broader frequency band

centered on the resonance frequency.

The increasing of the analysis band is often limited by the

presence of the high frequency signals that overlap that band.

Fault frequencies

The occurrence frequencies of the shocks resulted from the

faults in the bearings are called fault frequencies. They depend

on speed and bearing geometry. Knowing the speed, we can get a

direct relation between the measured fault frequency and the

type of flaw.

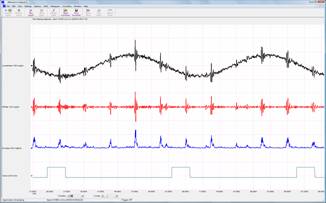

Enveloping

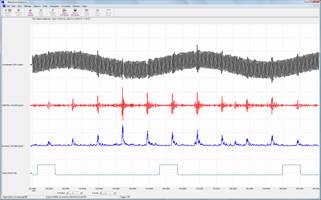

The vibrations signal envelope is a

low frequency signal that follows the peaks of the filtered

input signal.

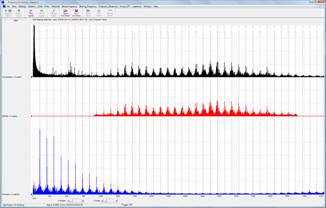

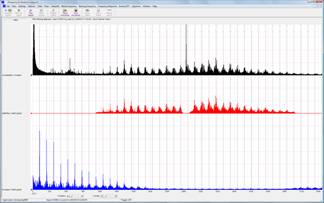

The envelope frequency spectrum

contains components with a frequency equal to the impact

occurrence rate and amplitude proportional to their energy.

The main steps in the vibrations

envelope analysis are:

-

Filtering

-

Enveloping

-

Decimation

-

Spectrum analysis

Bearings analysis with DSA 500

The 100 kS/s/ch acquisition speed,

24-bit resolution, and the 524288-sample analysis buffer make

the DSA 500 analyzer be fit for high accuracy diagnosis.

The Bearing Diagnosis function

monitors a range of waveform and frequency spectrum parameters

that are specific to bearing diagnosis.

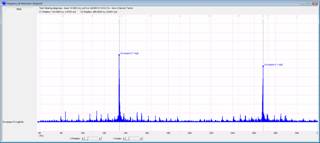

Fault frequencies are computed from

the input data on the bearing geometry, or loaded from a

user-customized database.

Cursors to identify the fault

frequencies, their harmonics and combined faults are available.

The vibrations signal may be

simultaneously process on multiple channels in order to monitor

both the overall machine status (overall vibrations, imbalance

faults and misalignments) and the status of one or more

bearings.

The analysis may be performed in the

frequency range for the constant speed regimes or order range

for the transient regimes.

Besides the specific bearing fault

noise, the vibrations signal contains certain signals of various

sources: imbalance, misalignment, gearing, and high frequency

noises.

Band-pass FIR filters remove these

components while keeping the position and amplitude of the

bearing’s faulty components unaltered.

The spectrum analysis of the input

signal and filtered signal leads to the overall assessment of

the machine and bearing status, and the optimization of the

filter.

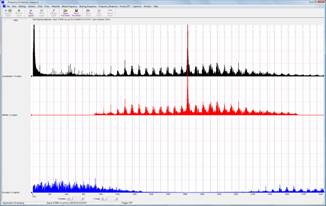

The envelope frequency spectrum

shows the fault type and gravity.

The enveloping operation is

sufficient provided that the bearing fault signal is being as

centered as possible on the zero value. The presence of a

perturbation in the resonance band may vertically translates the

fault signal so that it could not pass through zero anymore.

The presence of a perturbation in

the resonance band makes the envelope’s frequency spectrum not

contain the components specific to the bearing fault.

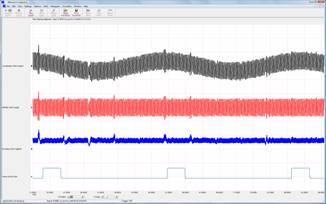

Multiple band-pass filtering allows

maintaining a broad analysis band by selecting those bands that

are not affected by unwanted signals.

The signal obtained is available for

both the envelope and the waveform analysis.

Keeping the bearing fault energy by

using the multiple band-pass filter helps identifying it in the

envelope spectrum even from the beginning.

Frequency resolution is an important

factor in the identification of the bearing faults and accurate

determination of the bearing’s functional and constructive

characteristics.

Through the decimation operation and

spectrum analysis over 262,144 lines, DSA 500 provides a

milihertz resolution while the frequency domain is tens of

kilohertz.

The parameters of the input,

filtered and envelope signals are recorded in a proprietary,

Excel or Access format for monitoring and trending the overall

condition of the machines over time.

Non-linear trends generally are an

indication of impending problems. This warning enables the

maintenance department to schedule the necessary repairs before

an unexpected failure occurs, causing downtime and lost

productivity.

Machine status network monitoring

DSA 401 helps monitoring multiple

machines over a wireless or cable network. High-speed data are

being sent to the analysis system for complete and high-accuracy

diagnosis.

Download pdf presentation

Download pdf presentation |