|

Rotor blades have infinite vibration modes

yet only the first ones have practical utilization.

The vibration mode frequencies are important

parameters for the blade testing as they are in direct relationship with

the mass distribution, design quality, and quality of shape, material,

finishing and mounting.

As for the rotor assembly, the analysis of

the resonance frequency leads to the identification of the loose or

cracked blades.

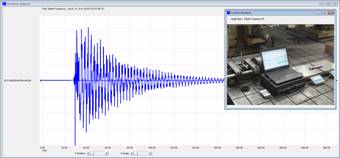

The

DSA 500 analyzer features special

functions to be used for testing optimization and processing of results:

-

Programmable

position and level triggering

-

Widely programmable acquisition frequency

-

FFT analysis on programmable time intervals

-

Automatic resonance frequency detection

-

Limit exceeding warning

-

Proprietary format and export to Excel

Equipment BSM 002 is being used to measure

the blade static moment.

Triggering functions automatically update

the data after each hit with the hammer.

Data acquisition continues up to the

completion of the whole buffer.

The FFT analysis of the vibrations may be

performed on the entire buffer or a programmable time interval with

various types of FFT windows.

The Blade Frequency Measurement

function automatically identifies within the FFT spectrum the

resonance frequencies and displays them in a easy-readable format.

Data is being exported into new files or

already existing files where it adds to previous recorded data.

Each data set is customized with the date, time, blade

number and operatorís name.

Download pdf

presentation

Download pdf

presentation |